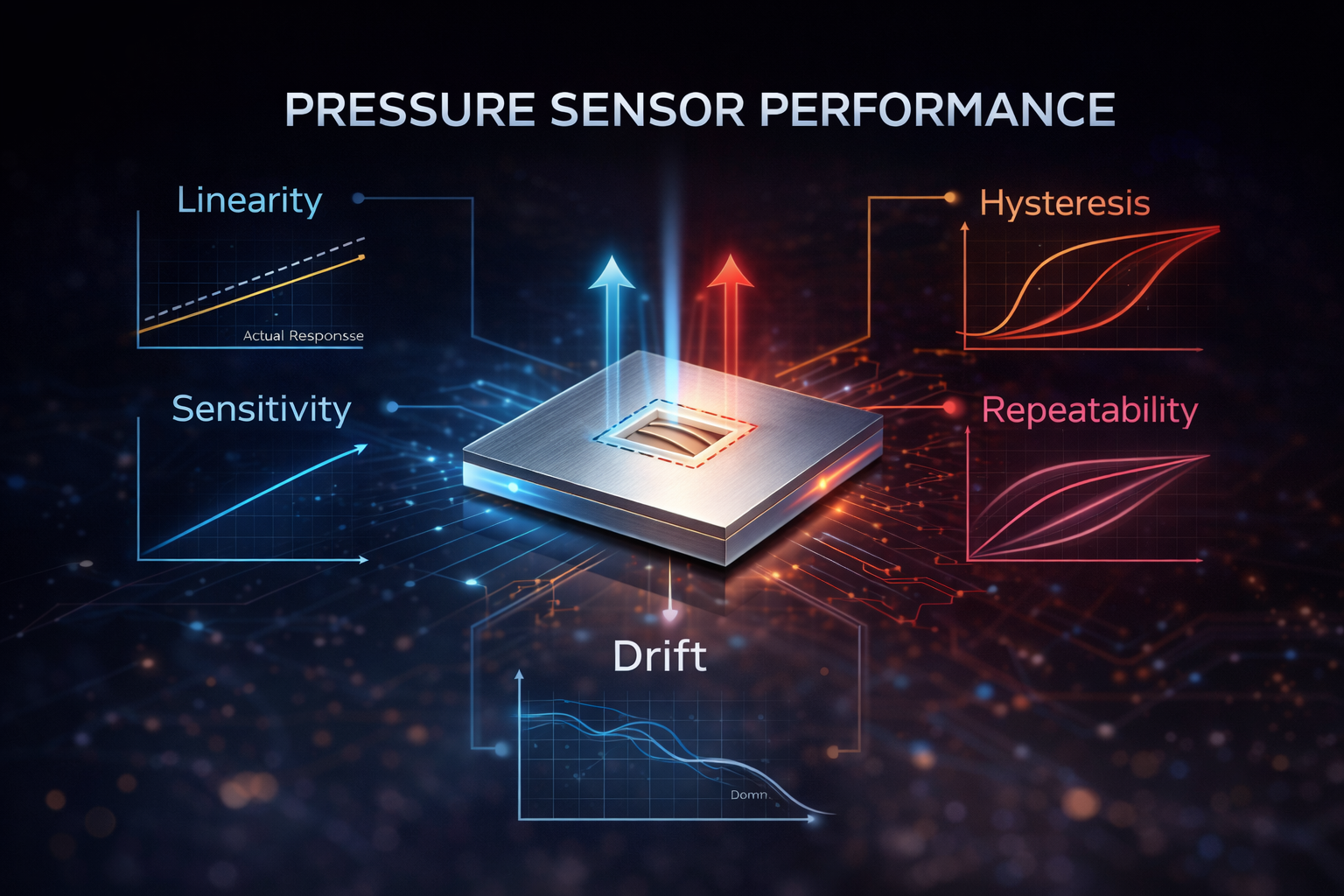

Key Performance Indicators of Micro Pressure Sensors

The performance of micro pressure sensors is mainly evaluated using several key indicators:

Linearity: Reflects the degree to which the actual relationship between sensor output and input deviates from the ideal linear fitting curve, and is a critical indicator of sensor accuracy.

Sensitivity: Represents the ratio of the change in output to the corresponding change in input, indicating the sensor’s ability to respond to small pressure variations.

Hysteresis: Describes the inconsistency of the output signal during increasing and decreasing pressure cycles, and is an important parameter for evaluating sensor stability and reliability.

Repeatability: Refers to the consistency of sensor output during repeated measurements, reflecting the sensor’s stability and reproducibility.

Drift: Refers to the phenomenon where the sensor output changes over time under constant input conditions, mainly caused by the sensor’s structural characteristics and environmental factors such as temperature and humidity.

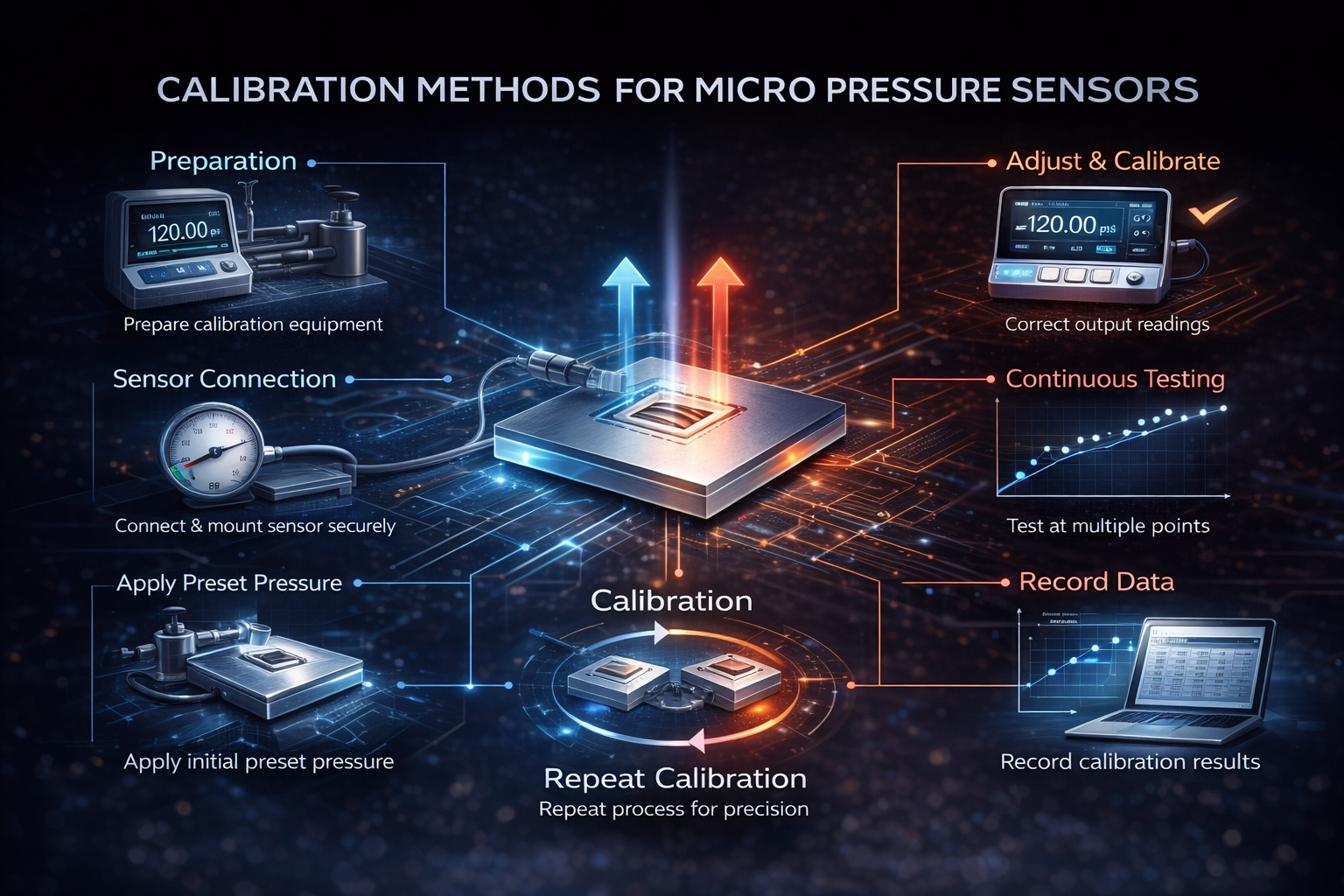

Calibration Methods for Micro Pressure Sensors

To ensure the accuracy and reliability of micro pressure sensors, regular calibration is essential. The calibration process typically includes the following steps:

Preparation of Calibration Equipment: Including high-precision pressure gauges, calibrators, and hydraulic pumps.

Sensor Connection: Connect the micro pressure sensor to the calibrator and ensure it is securely and stably mounted.

Application of Preset Pressure: Use the hydraulic pump to apply an initial preset pressure to the sensor, and read the actual pressure value using a high-precision pressure gauge.

Adjustment and Calibration: Correct and calibrate the sensor based on the initial readings to obtain accurate output values.

Continuous Testing: Adjust the pressure to multiple calibration points and continuously test the sensor’s output, observing its stability and accuracy.

Data Recording: Record all calibration data for subsequent analysis and reference.

Repeated Calibration: For multiple sensors or high-precision applications, repeat the calibration process multiple times to ensure measurement accuracy.

Conclusion

With their unique working principles, wide range of applications, critical performance indicators, and rigorous calibration methods, micro pressure sensors have become an essential component of modern technology and industry. As technology continues to advance and application demands grow, micro pressure sensors will play an increasingly important role across more fields, driving continuous industrial development and innovation.