As biped robots expand their applications into complex environments such as homes and offices, adaptability to various ground materials has become a critical challenge. Traditional vision and LiDAR sensors face limitations when dealing with transparent objects or low-light environments, and they cannot directly identify physical material properties. MEMS (Micro-Electro-Mechanical System) ultrasonic sensors with material recognition capabilities analyze echo energy differences, providing robots with strong penetration and high environmental robustness in material perception. This paper analyzes the technology from three aspects—technical principles, walking control optimization, and system integration validation—to elaborate on its innovative impact on gait planning, energy efficiency, and safety in biped robots.

1. Technical Principles: The Physics of Ultrasonic Material Recognition

1.1 Echo Energy Recognition Mechanism

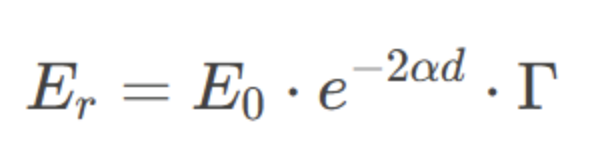

The MEMS ultrasonic sensor emits high-frequency sound waves above 175 kHz. The echo energy attenuation follows a formula involving the material’s acoustic impedance coefficient (Γ):

• Hard materials (e.g., tiles, wood floors): high acoustic impedance, strong echo energy

• Soft materials (e.g., carpet, sponge): low acoustic impedance, weak echo energy

The sensor distinguishes material types via threshold judgment or serial output.

1.2 Advantages of MEMS Miniaturization and Integration

Compared with traditional piezoelectric ceramic sensors, MEMS sensors are microfabricated, resulting in smaller size and lower power consumption. Their miniature transducer arrays support a 45°–180° field of view, enabling focused foot-surface detection.

2. Core Role in Biped Robot Walking

2.1 Adaptive Gait Parameter Adjustment

Biped robots must adjust joint stiffness and stride based on ground hardness:

• Hard surfaces (e.g., tiles): high step frequency, low damping — reduces slipping

• Soft surfaces (e.g., carpets): longer steps, lower foot pressure — prevents sinking

Example gait control rules:

if surface_type == HARD:

set_stiffness(hip_joint, 0.9) # Increase stiffness

set_step_length(0.6)

elif surface_type == SOFT:

set_stiffness(hip_joint, 0.6) # Decrease stiffness

set_step_length(0.4)

2.2 Anti-Slip and Stability Control

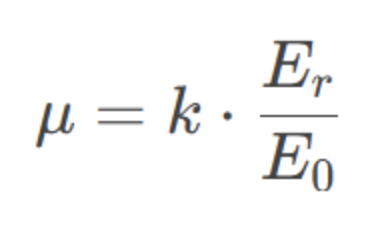

Practical experiments on commercial biped robots have proven the benefits of multi-sensor fusion. By combining ultrasonic material data with IMU information, a ground friction coefficient model can be built:

When low-friction surfaces (e.g., polished floors) are detected, the system pre-activates ankle compensation torque to prevent lateral slipping.

2.3 Energy Optimization

Energy consumption rises when robots move on soft materials. With material recognition, the driving strategy can be pre-adjusted:

• Hard surface: passive walking mode leveraging gravity for energy saving

• Soft surface: active drive mode with increased leg lift

Public data shows this strategy can reduce walking power consumption by up to 15%.

3. Installation and Timing Optimization

The sensor should be placed close to the foot (3–5 cm from the ground) and triggered mid-swing phase. Typical timing sequence:

• 50 ms after lift-off: trigger ultrasonic emission

• 100 ms before landing: complete material classification

• 50 ms before landing: adjust joint parameters

4. Application Cases and Performance Validation

4.1 Floor-Type Adaptation in Cleaning Robots

Ultrasonic material sensors (e.g., from ADW) have been applied in cleaning robots:

• Hard floors: activate mopping mode

• Carpets: increase suction, disable mopping

High material recognition accuracy enables seamless mode switching.

4.2 Biped Robot Gait Experiments

Integrating ultrasonic material sensors into biped robots has achieved:

• Reduced slipping incidents

• Improved stair-climbing success rate

• Lower energy consumption (maintaining ~0.8 m/s average walking speed)

5. Future Directions

• Multimodal Learning: Combine deep learning with spectral echo feature classification

• Array-Based Sensing: Use 2D MEMS arrays for material imaging

• Cross-Material Dynamics Modeling: Build a material–gait mapping database to support predictive control

Conclusion

The MEMS ultrasonic sensor with material recognition capability provides biped robots with a unique environmental perception dimension through acoustic feature analysis. Its contributions to adaptive gait control, anti-slip stability, and energy optimization make it a key enabling technology for robust walking in complex environments. With the ongoing integration of MEMS fabrication and intelligent algorithms, the environmental adaptability of biped robots will reach new heights.